The Yarra Valle Railway is currently undertaking the largest Volunteer Infrastructure Project in Australia – the full restoration of the Yarra Glen to Healesville rail corridor

With a restoration project as large as the one being undertaken by the YVR, there are many small wins which go unnoticed compared to the larger project milestones. This Special Clickety Clack Blog article follows one of these small wins, which involved Volunteers from four organisations working together across multiple locations and over the course of several weeks.

And the small win – the reproduction of heritage Gate Bolts to complete the Gates at Yarra Glen Station. Read more about the Heritage Platform Fence here and here.

The YVR would like to thank all Volunteers involved in this project, including the Yarra Glen Men’s Shed, corporate Volunteers from Ford Motor Company, Paul and Dietmar (Blacksmiths) and the Volunteers of the YVR. Congratulations on this achievement.

Gate Bolts for Yarra Glen Station

By Andrew, YVR Volunteer

When the new picket fence was built at Yarra Glen railway station three double gates and one pedestrian gate were included. They will provide access to the platform, in addition to the two barrier gates through the station building. In order that the gates can be held shut or held open, bolts were required. Fortunately we had bolts on the barrier gates which served as the design for seven new bolts which we have been able to make. Their manufacture has involved several people whose knowledge and skills have allowed the project to be accomplished.

The bolts on the barrier gate (left) served a design on which the new bolts were based.

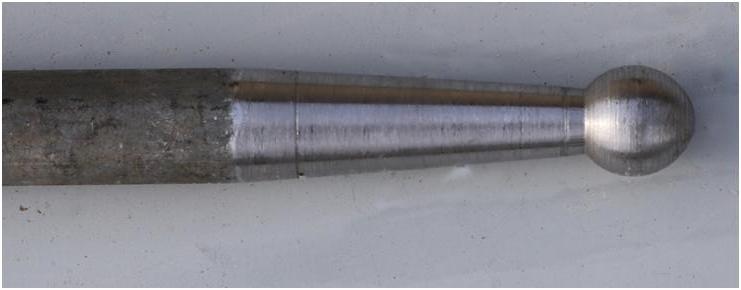

Fortunately we had several long ¾” (20mm) diameter bridge bolts. We took them to the Yarra Glen Mens’ Shed. John turned knobs on the end of the bolts and produced a taper leading up to the round knob.

While on a Ford Motor Company volunteer day at Yarra Glen, Lovisa (right) told me that there was a blacksmith at Emerald. She contacted him and he was happy to do the work required to assist in the fabrication of our gate bolts.

Below – Paul (right) and Dietmar (left) at the forge where they put a right angle on the bolts and forged saddles to hold them.

An angle grinder was used to shape the tops of the backing plates to which the bolt locating saddles were attached. The saddles were attached using short lengths of 6mm rod which were hammered to form rivets. Dietmar produced a tool to round the heads of the rivets.

The saddles were formed using a block that John at the Mens shed worked on in the lathe. The block was hammered onto the red hot steel to make the saddles . The individual saddles were cut using an angle grinder.

Three double gates and one single gate required 7 securing bolts.

The bolts are to betaken to be electro plated with zinc to prevent rusting and then painted black.

The pins to hold the bolts up and the stop blocks of two bolts were welded from the back by Andy using the MIG welder in the Healesville workshop. The other 5 I did in the Yarra Glen Men’s Shed using their MIG welder.

These long vertical bolts were found on many railway stations of the Victorian Railways. On stations where the heavy wooden barrier gates still exist many of these bolts remain. We suspect that in the past the Victorian Railways would have had their blacksmith apprentices make the bolts as part of their training.

In today’s world, the time to make them by hand would make them prohibitively costly. Our production of them is one of personal connections and community support. We are extremely grateful to all the people who have contributed to this project …Thank you!

The story does not end here. Dietmar took home a horizontal bolt (pictured below). We required three bolts altogether so Dietmar made two more for us.

Thank you Dietmar and to all Volunteers involved for the time and skill that you put into helping us with this project.

— Andrew, YVR Volunteer